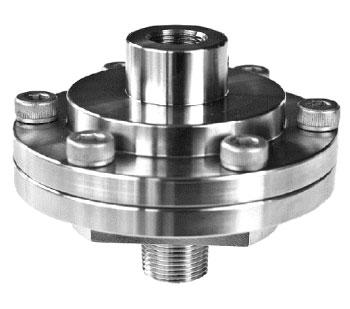

Diaphragm Seal Gauge with Clamped Construction & Screwed Connection

The Budenberg CSE is a high-integrity Diaphragm Seal Gauge that has been designed to withstand the high pressures and temperatures that are normally associated with Chemical, and Oil and Gas applications. The CSE has a diaphragm clamped between the upper and lower chambers thereby optimising the use of exotic materials for the wetted parts

Its unique feature is the ability to set the diaphragm to ‘lock off’ at set pressures thereby protecting the unit from major overload conditions, up to and including 400 Bar. This eliminates the need for expensive overload protection valves.

Available in a wide range of options including a choice of dial sizes, connections, materials, filling fluids, and options to permit operation at temperatures in excess of 440°c.

contact us for pricing and availability of the Budenberg CSE Diaphragm Seal Gauge

The Budenberg CSE is suitable for the following applications/industries

Designed for continuous operation on gases or liquids where the pressure element could become corroded or clogged by the process media. Versions are available to withstand pressure pulsations, vibrations, and operation at very high temperatures.

|

Pressure Gauge

|

Chemical

Pressure Gauge

|

Pressure Gauge

|

|

Water & Waste Water

Pressure Gauge

|

Food & Beverage

Pressure Gauge

|

Pharmaceutical

Pressure Gauge

|

The Budenberg CSE specifications

| Size | 63mm (2.5"), 100mm (4"), 150mm (6") |

| Accuracy Class |

1.0% as defined in EN837

|

| Pressure Range |

The welded seal units are available in a range of configurations depending on the required Dial Size and Operating Pressure range as follows:

Dial Size - 63mm / 100mm / 150mm

Seal Diameter - 69mm

Min Range - 1 Bar

Max Range - 400 Bar

|

| Over Range Protection |

All units will withstand 130% overload as standard up to 200 Bar. Optionally the diaphragm can be set to 'lock off' allowing the unit to withstand an overload up to the maximum pressure rating of the seal unit. This unique feature can be used to avoid the use and cost of additional overload protection valves.

|

| Materials of Construction |

Due to the clamped construction, all materials including the diaphragm and connection can be the same material or a combination of several.

Standard - 316L Stainless Steel

Options (CSER) - Hastelloy C276, Titanium, Tantalum or Monel 400.

Teflon lined connection on BSP only, with other materials available on request.

|

| Process Connections |

Model CSE hs male connections of:

1/4", 3/8", 1/2", 3/4", 1" BSP or NPT

Model CSI has female connections of:

1/4", 3/8", 1/2", 3/4", BSP or NPT

Other connections are also available

|

| Filling Fluids |

A wide range of filling fluids is available to suit most applications including high-temperature and pharmaceutical applications.

Standard Options - Mineral Oil, Silicon HT Oil, Medicinal Paraffin, Glycerine, Syltherm XLT & 400.

Inert Fluorine-based fluids can be specified for oxygen and chlorine applications as well as a range of FDA-approved fluids for food and pharmaceutical applications.

|

| Temperature |

Normal process operating temperature range: -20 to +100°c

Elevated temperature operation up to 450°c can be achieved by the selection of an extended neck option and an associated high-temperature filling fluid.

|

| Pulsation Dampener | The clamped design allows Budenberg to offer a snubber internally to dampen pulsations and beneficially protect the Pressure Gauge. |

| Certification & Traceability |

Serial Number Printed on Dial.

A certificate of Conformity traceable to National Standards is supplied

|

| Safety | All units are manufactured to comply with EN837-1, S3 Specification, and other regulatory standards including PED. |

CSE Specification Sheet Download

To view all the information on the Budenberg CSE you can download the datasheet here