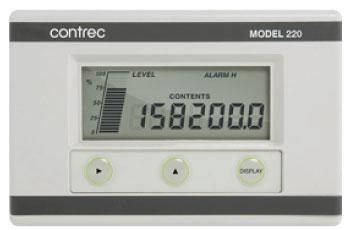

Contrec's Model 220 Loop Powered Level Monitor accepts a 4-20mA signal from a wide range of level sensors, including pressure transmitters, ultrasonic sensors, or capacitance probes, and displays both level and tank contents on a large LCD display.

Contrec's Model 220 Loop Powered Level Monitor accepts a 4-20mA signal from a wide range of level sensors, including pressure transmitters, ultrasonic sensors, or capacitance probes, and displays both level and tank contents on a large LCD display.

The 220 is a highly accurate, intrinsically safe level monitor that has been designed to operate with digital output flowmeters. With an IP67 weatherproof housing, a new tactile keyboard, and various mounting options the 220-level monitor is perfect for the most arduous of installations.

The solid-state relay outputs provide up to four level alarms and a 25-point non-linearity correction table that allows the instrument to be programmed to fit most tanks. This Level Monitor is powered entirely from the 4-20mA current loop requiring no external power or batteries.

This versatile instrument is fully programmable with setup parameters such as span, offset, alarm levels, etc, stored in a non-volatile memory that will retain all data for more than 10 years without power.

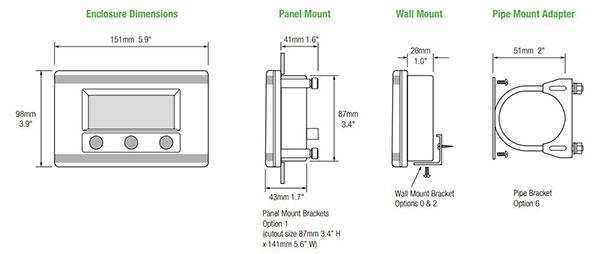

A wall mounting bracket is supplied as standard, while a 2″ pipe mounting bracket is available as an option. Alternatively, the Model 220 can be supplied as a panel mount instrument. The Model 220 is housed in an attractive IP67 (Nema 4X) polycarbonate enclosure which is completely watertight.

220 Level Monitor features

- Non-linear Tank Correction

- Density Correction

- Four Level Alarms

- Level Bar Graph Display

- Tank Contents Display

- Powered by 4-20mA Loop

- Intrinsically Safe

- Wall, Pipe, and Panel Mounting

- Watertight to IP67 (Nema 4X)

- ATEX, IECEx, CSA Approved

- CE Compliant

Display

Relays

Non-Linearity Correction

A 25-point non-linear correction table can be programmed to handle any shaped tank. Up to 25 points on both the x and y axes can be programmed and the Model 220 will perform linear interpolation between points. The curve enables the contents of vessels, such as cylindrical tanks, bullet-shaped tanks or hoppers to be displayed directly in engineering units as a volume or mass. A conversion program that runs under Windows 95 is available to calculate theoretical values for the conversion program based on tank dimensions.

Intrinsic Safety

The 220 is certified as intrinsically safe to European ATEX / IECEx standards and CSA US/C standards for both the USA and Canada (refer to specification details for more information)

220 Loop Powered Level Monitor Specifications

| Display | Type |

LCD Display

|

| Level | 20 segment bar graph | |

| Level Span |

0...100% proportional to input signal

For non-inverting tanks 0% is 4mA and 100% is 20mA

For inverting tanks 0% equals 20mA and 100% is 4mA

|

|

| Contents |

7 digits with 12mm high digits on teh LCD. Contents are displayed with 42 digit resolution and trailing zeros

|

|

| Contents Span | The contents span is programmable in the range of 0.000...9,999,999. The contents zero is the contents in the tank at 0% level | |

| Decimal Points | Decimal point position for contents is programmable in range of 0...3 decimal point places | |

| Physical | Operating Temperature | -20°C to +60°C |

| Enclose Dimensions | 98mm x 151mm x 43mm | |

| Protection | Sealed to Nema 4X or IP67 standards | |

| Wall Mounting Options |

Wall: Universal wall mounting bracket

Pipe: A galvanised metal bracket is available which enables the Model 220 to be attached to a 51mm (2") vertical or horizontal pipe

Panel: Supplied with mounting brackets. Terminals accessible from the rear. (Note: that the panel mount version is not watertight)

|

|

| 4-20mA Power Input | Resolution & Linearity | 0.05% of span |

| Accuracy |

0.05% of span @ 25°C

0.1% (typ) of span, full temperature range

|

|

| Update Time | 0.5 second | |

| Connection | Two wire | |

| Voltage Drop | 2.5 volts maximum | |

| Alarm / Pulse Outputs | Type | 4 x open collector outputs suitable for driving DC solenoids or external relays. The outputs provide high, high-high, low and low-low flow alarms |

| Switching Power | 200mA. 30Vdc maximum | |

| Saturation Voltage | 0.8Vdc typical across the output in the "on" state | |

| Isolation | Outputs are separately optoisolated | |

| Hazards Area Approval | ATEX | Rating - II 2G Ex ia IIB T4 Gb [Cert No. BVS 15 ATEX E 106 X] |

| IECEx | Rating - Ex ia IIB T4 Gb [Cert No. IECEx BVS 15.0099X] | |

| CSA US/C | Rating - Class 1, Group C & D [Cert No. 104840-5] | |

| Intrinsically Safe Parameters | Maximum Ambient | 60°C |

| Maximum Input Parameters |

4-20mA or Relays

Ui = 28V

Ii = 93mA

Pi = 653mW

|

|

| Maximum Output Parameters |

Relay

Ui = 28V

Ii = 93mA

Pi = 653mW

|

220 Level Monitor Drawings for product dimensions