The Contrec 505 BC01 Batch Controller is a dual-stage application batch controller for the reliable measurement of preset quantities using a volumetric frequency input. It can be used as a single or dual-stage controller and it is suitable for fast batch applications providing the operator with clear local readout and can be controlled via communications in more automated systems.

The Contrec 505 BC01 Batch Controller is a dual-stage application batch controller for the reliable measurement of preset quantities using a volumetric frequency input. It can be used as a single or dual-stage controller and it is suitable for fast batch applications providing the operator with clear local readout and can be controlled via communications in more automated systems.

When access is authorised there is quick access to commonly used preset values directly from the front panel. Automatic overrun compensation caters to system delays such as valve closure for precise volumes.

The 505 BC01 instrument is compatible with a wide range of flowmeter frequency outputs, including millivolt signals, reed switches, Namur proximity switches, and pulse trains via its smart front-panel program selection.

505 BC01 Dual Stage Batch Controller features

- Tailored for volumetric frequency flow input

- Single or Dual stage control

- Quick access to common batch quantities

- No-flow, leakage, and overflow error detection

- Remote RUN/STOP/RESET

- Allows for non-linear correction

- Storage of 100 transactions with time and date stamp

- Selection of second language and user tags

- Selectable protocols on serial ports including Modbus RTU and Printer output

- Backlit display with LCD backup

Displayed Information

The front panel display shows the current values of the input variables and the results of the calculations. A list of the variables for this application and their type (total or rate) is shown at the end of this document.

The instrument can be supplied with a real-time clock for storage of up to 100 transactions with time and date stamps.

Communications

There are two communication ports available as follows:

- RS-232 port

- RS-485 port

The ports are available for remote data reading, printouts, and for initial application loading of the instrument.

Retransmission & Control Outputs

The instrument can retransmit any main menu variable. The digital outputs can retransmit totals as pulses or operate as logic levels for control or error outputs. If the instrument has the advanced option, it outputs rates as a 4-20 mA signal.

Relay Outputs

The relay outputs 1 and 2 are used to control the flow of product for each delivery. These contacts are normally open and can be used to drive external relays, valves, pump circuits, etc.

Software Configuration

The instrument can be further tailored to suit specific application needs including units of measurement, custom tags, second language or access levels. A distributor can configure these requirements before delivery. Instrument parameters including units of measurement can be programmed in the field, according to the user access levels assigned to parameters by the distributor.

All set-up parameters, totals, and logged data are stored in non-volatile memory with at least 30 years of retention.

Calculations for the 505 BC01 Batch Controller

The total and flowrate are derived from accurately measured frequency and the number of received pulses.

volume = pulses / k-factor

volume flow = frequency / k-factor

Automatic overrun compensation calculates the new valve closure point to ensure correct delivery by averaging the overrun amount from the last three complete batches.

The overrun compensation value is valid for a new preset value provided the stored overrun is less than 20% of the new preset.

505 BC01 Specifications

| Operating Environment | Temperature |

0°c to +60°c (conforma coating)

+5°c to +40°c (no coating)

|

| Humidity |

0 to 95% noncondensing (conformal coating)

5% to 85% noncondensing (no coating)

|

|

| Power Supply |

95 - 135V AC or 190 - 260V AC or 12 - 28V DC |

|

| Consumption | 6W (typical) | |

| Protection | Sealed to IP65 (Nema 4X) when panel mounted | |

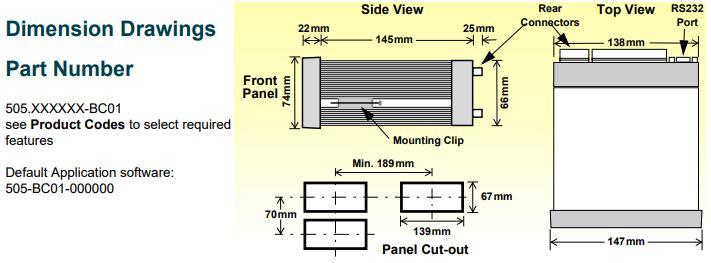

| Dimensions | 147mm (w) X 74mm (h) X 167mm (d) | |

| Display | Type | Backlit LCD with 7-digit numeric display and 11-character alphanumeric display |

| Digits | 15.5mm high | |

| Characters | 6mm high | |

| LDC Backup | Last data visible for 15 minutes after power down | |

| Update Rate | 0.3 second | |

| Non-volatile Memory | Retention | > 30 years |

| Data Stored | Setup, Totals, and Logs | |

| Approvals | Interface | CE compliance |

| Data Stored | IECEx, ATEX, and CSA approved enclosures available for hazardous area | |

| Real-Time Clock (optional) | Battery Type | 3 volts lithium button cell (CR2032) |

| Battery Life | 5 years (typical) | |

| Frequency Input (general) | Range | 0 to 10kHz |

| Overvoltage | 30V maximum | |

| Update Time | 0.3 seconds | |

| Cutoff Frequency | Programmable | |

| Configuration | Pulse, coil or NPS input | |

| Non-linearity | Up to 10 correction points | |

| Pulse | Signal Type | CMOS, TTL, open collector, reed switch |

| Thershold | 1.3 volts | |

| Coil | Signal Type | Turbine and sine wave |

| Sensitivity | 15mV p-p minimum | |

| NPS | Signal Type | NPS sensor to Namur standard |

| Remote Logic Inputs | Signal Type | Voltage free contact, open collector |

| Relay Output | No. of Outputs | 2 relays |

| Voltage | 250 volts, AC, 30 volts DC maximum | |

| Current | 3A maximum | |

| Communication Ports | Ports | RS-232 port |

| Baud Rate | 2400 to 19200 baud | |

| Parity | Odd, even or none | |

| Stop Bits | 1 or 2 | |

| Data Bits | 8 | |

| Protocols | Modbus, RTU, Printer* | |

| Transducer Supply | Voltage | 8 to 24 volts DC, programmable |

| Current | 70mA @ 24V, 120mA @ 12V maximum | |

| Protection | Power limited output | |

| Pulse/Digital Output | Signal Type | Open collector, non-isolated |

| Switching | 200mA, 30 volts DC maximum | |

| Saturation | 0.8 volts maximum | |

| Pulse Width | Programmable: 10, 20, 50, 100, 200 or 500ms | |

| 4-20mA Output (optional) | Supply | 24 volts DC internal, non-isolated |

| Resolution | 0.05% full scale | |

| Accuracy | 0.1% (full temperature range, typical) |

505 BC01 Drawings for product dimensions