Flow Profile Optimisation for Accuracy

Flow Profile Optimisation for Accuracy

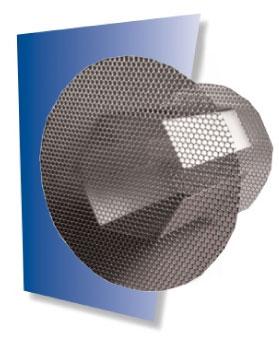

The Sierra Instruments’ Flow Conditioning Plates represent an economical solution to the problems commonly associated with monitoring flow installations where long, straight runs of piping are not available.

The flow conditioning element effectively eliminates velocity profile distortions, swirl, and temperature stratification in the gas stream. The flow conditioner creates a uniform velocity profile by means of two stainless steel perforated plates. The FlatTrak has been designed to work in schedule 40 pipe (for other schedules contact Procon) with 150# flanges, the front flow conditioning screen is sandwiched between two 150# flanges, along with two 1/8” gaskets (gaskets and flanges are supplied by customer).

The flange mounting bolts serve to center the screen in place and the flow plates reduce upstream piping diameters to less than three diameters after most common flow disturbances. Sierra Instruments have carried out extensive testing that has demonstrated that the FlatTrak virtually eliminates the effect of piping conditions with fewer upstream diameters than any other flow conditioning technique. Flow plates may be purchased separately for general flow conditioning or they may be used with existing Sierra insertion meters if calibrated as a set.

Featuring

- Creates uniform flow profile at an economical price

- Maximizes flow measurement accuracy in constrained piping environments

- Reduce upstream and downstream diameters

- Proven Dual-Plate technology

Industries: Oil & Gas / Petrochemical / Facilities Management / OEM / Hazardous Area / Gas Distribution & Allocation

Benefits of Sierra's FlatTrak

- Reduce upstream piping diameters to less than 3 diameters

- Use inline upstream of any gas flow meter.

- Ideally suited for point velocity insertion-type flow meters like thermal mass.

- Designed for schedule 40 pipe with 150# flanges (for other schedules, contact factory)

- The upstream element is sandwiched between two 150# flanges, along with two 1/8” gaskets

- Flange mounting bolts serve to center the screen in place.

- 316 stainless-steel construction (other materials upon request)

- Greatly reduces straight-run requirements

- Low-pressure drop

- May be used in very large-diameter pipes

- Designed for use with ANY point-velocity flow measurement device

Applications suitable for use

- One 90° Elbow: FlowTrak (1) upstream; Oricice plate (28) upstream

- Two 90° Elbows Same Plane: Flow Trak (3) upstream; Oricice plate (36) upstream

- Two 90° Elbows Different Planes:Flow Trak (3) upstream; Oricice plate (62) upstream

- Reducer - 4/1: FlowTrak (3) upstream; Oricice plate (14) upstream

- Globe Valve - Fully Open: FlowTrak (2) upstream; Oricice plate (32) upstream

FlatTrak Specification Sheet Download

To view all the information on the FlatTrak by Sierra Instruments you can download the datasheet here